Round 5: Baby Steps

Sorry for the lengthy write-up but I have quite a bit to report and want to make this process easier for anyone attempting it in the future.

We had some down time trying to sort out the rear differential and I was also dreading the 5 speed conversion. I had removed all of the parts at the junkyard (brake pedal assembly, clutch pedal/MC/line, shifter and linkage) so knew what was involved and it was going to be a huge pain. As you all know, the brake booster is on the passenger side which means the bar connecting this to the pedal is running behind the HVAC components. I don't mind breaking parts at the junk yard but obviously don't want to damage my own car.

Since my AC system was working great I wanted to try to keep it all intact. We removed the compressor from the motor when we pulled the 4G64 and it looks like it will bolt up to the 4G63 just fine. The issue, however, is gaining access to swap out the brake pedal. Another problem is that my AC system is the old kind using R12 and I don't think its ever been converted (no sticker saying R134 anywhere) so the cost to get the system working again once its evacuated would be pretty hefty (something I obviously wanted to avoid).

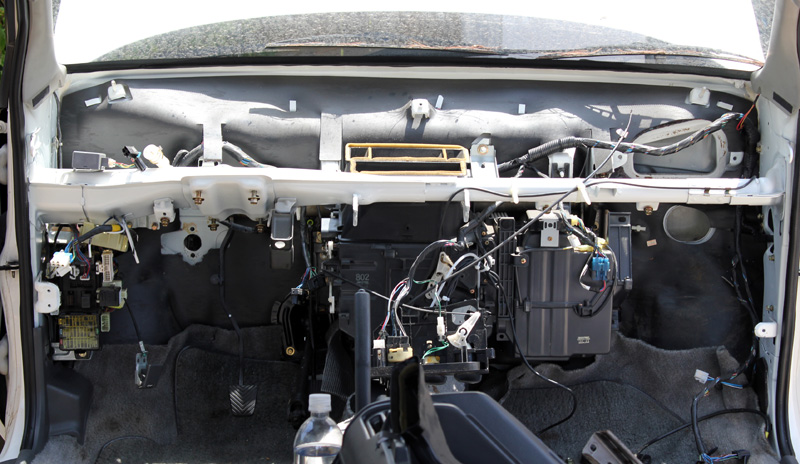

As you will see below, I pulled the dash and gained access to the pedal assembly and HVAC components. After taking a close look at everything I decided to first remove the blower motor on the passenger side of the car since this wouldn't require disconnecting any of the AC lines and would still allow me to remove the engine wiring harness (which also runs behind the HVAC components over to the stereo where the auto trans ECU is located). In the third picture below you can see how the brake pedal ties in to the booster.

The pedal is welded to the other end of this bar so the only way to actually remove the brake pedal is to disconnect it on the booster side of the car. After a closer look I was thinking about disconnecting the pin that connects to the booster and remove the C-clip on the end so the bar could slide out without the bulky brake booster bracket. Unfortunately, it still looked like it would be close to impossible to get the bar out since it is fairly long (not much room to free it on the driver side) and the metal tab that connects to the booster looked to be in the way as well.

We did a test fit with the clutch pedal assembly and it was barely making contact with the auto brake pedal. So I took a close look at the brake pedal from the manual car and compared it to the auto. The arm that comes down from the bar looked identical with the only difference being a small pin welded at the top on the auto and a smaller pedal at the bottom of the manual one. It appears as though the factory uses the same arm and simply welds on a different pedal for each application. It was time to start cutting. I used the pedal pad as a template and cut the excess off of the brake pedal. I had to do some more trimming after the first two major cuts but am VERY pleased with the outcome.

As expected, the auto and manual assemblies use the same bolts for their brackets and the firewall is even stamped for the clutch master cylinder. I found a hole saw that was the perfect size and did some quick cutting and cleaned it up with a file.

Inside the car.

Engine bay.

Here is a shot of the shifter installed. The Vista/LRV/Summit shifter assembly is definitely different than the Colt hatchback. The shifter works in the same fashion but the mounting holes are different and they employed a longer shifter since you sit higher in these cars. I also found an LRV steering wheel at the yards for about $15 so threw that in as well. It has 4 posts and the entire center is the horn whereas the Vista had 2 posts and buttons on the sides. Cheap and much sportier look...and I like the DSM badge. Ultimately, I'd like to get a Colt Turbo or aftermarket wheel but this will work for now.

Heres a shot of the 4G63 harness installed. The clips that tie in to the chassis are different so I need to hunt down a Vista wiring diagram and figure that out. Shouldn't be too difficult once I find that. Since the harness is much longer (the Vista ECU is mounted on the passenger side wall under the dash) I am going to run the wires over to the center console and mount the 4G63 ECU where the Vista trans ECU was located. Much easier and cleaner than the alternatives.

So, the rear differential was a big concern. The Eclipse rear axles slide in to the diff and bolt to the stubs on the outside. The Vista has the opposite set up with the stubs mounted in the diff. Although the rear ends look very similar (see below) there are a few differences. They both mount to the rear moustache bar the same way. However, the front half of the case is different. The Vista has a soft mount and employs 2 bolts on each side and uses 1 bolt on the top. The Eclipse only has 2 bolts on the side and uses 2 bolts on top. Since it didn't look like a straight swap we took both diffs to a transmission shop to see what the options were.

A week later they called back and said they could put the stubs in the Eclipse rear (small compromise since it uses less bolts on the side) for $375. If I wanted all of the guts swapped over it would be $650. I decided to pick up the diffs and think about it. Worse case scenario we figured it was worth trying to swap everything ourself and if it didn't work we were in the same position having to pay to have the work done. Both of the back covers were off and one axle stub had been removed from the Vista diff but I was in a hurry so dropped them at Dan's house and took off. A few hours later Dan called and said he had a rear diff ready to install! The Vista axle stubs use retaining clips just like front axles so are fairly easy to remove. Fortunately, they also slide right in to the Eclipse 3-bolt rear. Needless to say, the trans shop was going to rip me off big time w/ the $375 quote to simply swap the axle stubs! I'm going to call and give them (Certified Transmission) a piece of my mind. In my opinion, this type of business practice is totally unacceptable and I will NEVER recommend this shop to anyone.

Vista Rear Diff. You can see the 4 prongs on the side for the bolts and the 2 in the top. As you will notice, only one on the top looks used because the Vista only uses one bolt. I'm assuming this would bolt directly in to an Eclipse since it uses 2 bolts on the top.

Vista axle stubs installed in the Eclipse 3-bolt rear. In the second picture you will see where the other 2 bolts would go on the Vista diff but the Eclipse doesn't have provisions for this. I don't think this will be an issue so am only going to address it if it becomes one.